Description

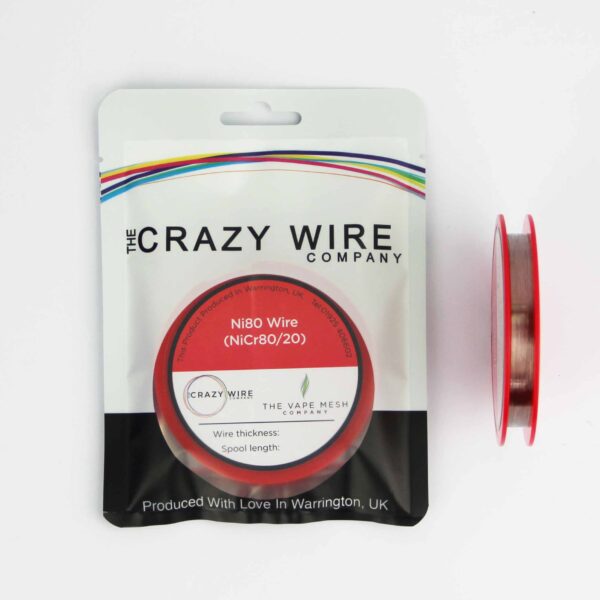

Ni80 Resistive Heating Wire

The Crazy Wire Company are best know as suppliers of top quality Ni80 resistive heating wire. We have enormous stock levels at all times, as we use this wire to weave our high-specification woven mesh products. Our brilliant staff are experts in producing our spools of round wire on our 6 rapid action winding machines. All spools are produced to carry a little extra length to make up for any waste when handling the product.

The 0.125mm (36 AWG) Ni80 resistive heating wire is crafted from an 80% Nickel and 20% Chromium alloy. It offers exceptional resistance stability for consistent temperatures. By limiting its thickness to 0.125mm, this heat-up device is both energy-efficient and quick to heat up. Wires like this are ideal for using in small electric heaters, resistive load banks, and some industrial heating applications. As a result of its consistent resistance, the heater ensures even heating and reduces the chances of hot spots. Due to its Ni80 composition, it is resistant to oxidation and is durable and long-lasting under high temperatures. A range of heating applications can be served with this resistive heating wire by providing reliability and efficiency.

A 0.125mm Nichrome heating wire is a thin wire made of Nichrome alloy that is commonly used in heating elements and resistance wire applications. The diameter of the wire is 0.125mm, which is relatively small compared to other types of wire.

Key product details:

- Diameter – 0.125mm (125 Micron – 36 AWG)

- Ohms/m – 88.82

- Technical Specification:

- Ni – Rest

- Cr – 20.0 – 23.0

- Fe – <1.0

- Max Continuous Service Temp Of Element – 1200

- Micrographic Structure – Austenite

- Magnetic Properties – Nonmagnetic

- Electrical resistance is high

- Corrosion resistance is high

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

We do not only offer Ni80 round wire. We also have a huge range of KA1 and stainless steel round wire in immediate stock too.

Ribbon wire and flat wire are stocked for immediate dispatch too.

FAQs About This Wire

At What Temperature Does Nichrome Wire Glow Red?

The temperature at which Nichrome wire glows red depends on several factors, including the composition of the Nichrome alloy, the wire’s diameter, and the current passing through the wire.

Typically, Nichrome wire begins to glow red when its temperature reaches around 700°C to 900°C. At these temperatures, the wire begins to emit light in the visible red spectrum. This is why it appears to glow red. The exact temperature at which Nichrome wire begins to glow red can vary depending on the specific composition of the alloy, the wire’s diameter, and the current passing through the wire.

What Can A Hot Wire Cutter Cut?

A hot wire cutter is a tool that uses an electrically heated wire to cut materials such as foam, plastic, and other soft materials. The hot wire is typically made of Nichrome or other high-resistance materials and is heated by passing an electrical current through it. When the wire comes into contact with the material to be cut, the heat from the wire melts or vaporises the material, allowing it to be easily cut.

Materials that can be cut using a hot wire cutter include:

Foam: Hot wire cutters are commonly used to cut foam for use in a variety of applications, including packaging, insulation, and model-making.

Plastic: Hot wire cutters can be used to cut a variety of plastic materials, including polystyrene, polyethylene, and PVC.

Soft woods: Some hot wire cutters can be used to cut soft woods, such as balsa, for model-making or other applications.

Other soft materials: Hot wire cutters can also be used to cut other soft materials, including wax, rubber, and some types of composites.

It’s important to note that hot wire cutters are not suitable for cutting materials that are too dense or hard, such as metals, glass, or stone. They are also not suitable for cutting materials that are flammable or emit toxic fumes when heated, such as certain types of foam or plastics.

Which Is Better Nichrome Or Tungsten?

Nichrome and Tungsten are both materials that are commonly used in high-temperature and high-resistance applications. The choice of which one is better depends on the specific requirements of the application.

Advantages of Nichrome:

- has a higher resistance compared to Tungsten, making it a better choice for heating applications where a high resistance is required to generate heat.

- is more flexible and easier to work with compared to Tungsten, which is brittle and can be difficult to bend or shape.

- has a lower melting point compared to Tungsten, making it easier to work with at high temperatures.

Advantages of Tungsten:

- has a much higher melting point compared to Nichrome, making it more suitable for high-temperature applications where the material will be exposed to extreme heat for an extended period of time.

- is a much more durable material compared to Nichrome, and is less likely to degrade or break over time when exposed to high temperatures.

- has a higher thermal conductivity compared to Nichrome. This makes it a better choice for applications where heat needs to be evenly distributed or transferred quickly.

How Long Can Ni80 Last?

The lifespan of Nichrome wire depends on several factors. This includes the specific composition of the Nichrome alloy, the operating temperature, and the current density. In general, Nichrome wire can last for many years with proper use and maintenance.

However, operating Nichrome wire at high temperatures or with high current densities can reduce its lifespan and lead to thermal degradation. Over time, the Nichrome wire may become brittle or suffer from other forms of degradation. This can reduce its effectiveness as a heating element.

To maximize the lifespan of Nichrome wire, it’s important to use it within its specified temperature range and to ensure that the current density is within the recommended limit. Regular maintenance and inspections can also help to extend the lifespan of Nichrome wire by detecting and addressing any potential issues before they become serious problems.

Check out our blog ‘what is nichrome‘ for more information on ni80 wire in general. Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

Reviews

There are no reviews yet.