Description

Stainless Steel Wire

The Crazy Wire Company are long established as Europe’s preferred suppliers of top quality 316L grade stainless steel wire. We have enormous stock levels at all times, as we use this wire to weave our marine grade woven mesh products.

The 0.28mm (29 AWG) ss316l marine grade steel wire is meticulously crafted to meet a diverse array of applications, especially in environments with high corrosion and oxidation resistance requirements. The stainless steel wire is crafted from the specific alloy ss316l, which is not only resistant to corrosive elements like seawater and acidic substances, but also highly durable and strong. This steel wire is widely used in marine environments for rigging ships, creating safety barriers, and making marine fasteners. As well as its use in electronics, its ability to withstand high temperatures without compromising its structural integrity makes it useful in temperature control coil applications. It is also employed in the construction industry for its ability to support sturdy and reliable structures and frameworks, ensuring stability under difficult circumstances.

This stainless steel wire is a preferred choice for surgical procedures and medical device manufacturing due to its biocompatibility and resistance to body fluids. Additionally, jewelers use SS316L steel wire for creating intricate and durable pieces that are resistant to tarnishing. Providing a reliable solution across several domains, the corrosion-resistant, versatile, and durable steel wire demonstrates the innovative amalgamation of strength and resilience, ensuring optimum performance and longevity across industrial and artisanal applications.

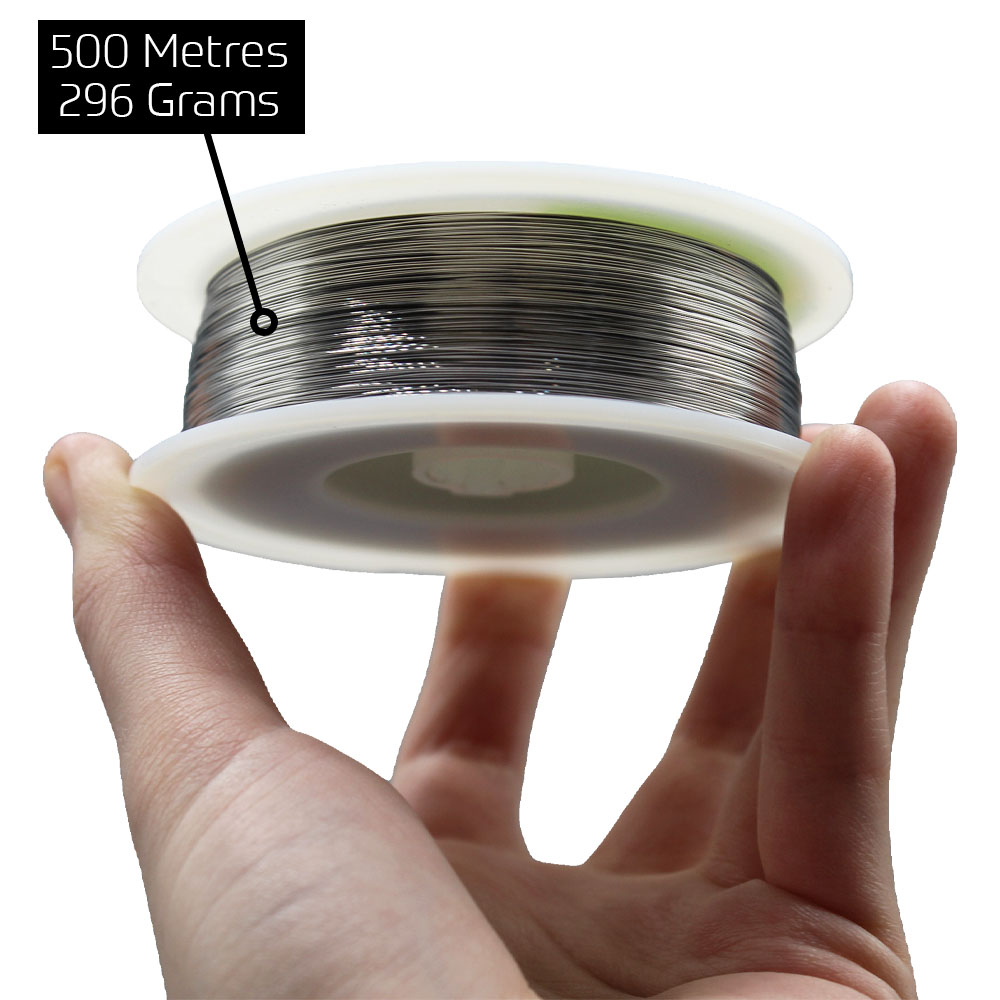

Specification of Wire:

- Diameter – 0.28mm (29 AWG)

- ohms/m – 12.18

We also offer this grade as ribbon wire and flat wire too if required.

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

Not only do we offer 304 grade stainless steel wire, but we also stock huge levels of SS316, SS430 (magnetic) and SS317L.

We also offer stainless steel in ribbon and flat wire options.

The choice is virtually endless!

FAQs About This Wire

How Does SS316l Steel Wire Perform Under Extreme Weather Conditions?

As a result of its special alloy composition, ss316l steel wire exhibits commendable performance under extreme weather conditions. Even in harsh coastal environments and arctic temperatures, this marine-grade steel wire maintains its integrity and offers high tensile strength and corrosion resistance. When exposed to moisture or high humidity, the chromium in SS316L alloy provides a robust defense against oxidation. Additionally, molybdenum provides additional protection against pitting and crevice corrosion in chloride environments. The 316l steel wire retains its structure and surface quality under the abrasive conditions of sandstorms. Despite extremely high temperatures, the wire retains its shape and strength due to its excellent thermal resistance. Therefore, ss316l steel wire can withstand extreme weather conditions and maintain performance and safety in different applications.

Is SS316l Steel Wire Resistant To Oxidation?

Absolutely, the ss316l steel wire holds a substantial resistance to oxidation, a trait inherently rooted in its specific alloy composition. The “316” in ss316l refers to a grade of stainless steel that contains molybdenum, which enhances its resistance to pitting and provides an elevated level of resistance against several chemicals. Furthermore, the significant chromium content plays a pivotal role in protecting the wire against oxidation. When exposed to oxygen, whether in the air or water, the chromium within the steel reacts to form a passive layer of chromium oxide. This protective layer serves as a shield that isolates the steel from an oxidative environment, preventing rust and maintaining the wire’s integrity and appearance. Moreover, the “L” in ss316l denotes “low carbon,” which reduces the risk of sensitisation during welding and ensures superior corrosion resistance in welded structures, thus maintaining its resistance to oxidation even after fabrication processes. Consequently, ss316l steel wire sustains its structural and aesthetic properties, even in environments where oxidation is commonly a significant concern, endorsing its utility in numerous applications where both durability and longevity are essential.

Why Choose Marine Grade SS316l Steel Wire For Marine Applications?

Choosing marine grade SS316L steel wire for marine applications brings forth a suite of advantages, most paramount being its exceptional resistance to corrosion, particularly in chloride-containing environments like seawater.

- Exceptional Corrosion Resistance: SS316L steel wire withstands the saline and often corrosive conditions of marine environments due to its enhanced corrosion resistance, particularly against pitting and crevice corrosion, thanks to its molybdenum content.

- High Tensile Strength: It possesses significant tensile strength, enabling it to endure considerable physical stress and variable loading conditions prevalent in marine applications.

- Low Carbon Content: The “L” signifies low carbon content, which not only aids in avoiding carbon precipitation during welding but also mitigates susceptibility to granular corrosion, ensuring maintained structural integrity.

- Durability in Harsh Conditions: Ability to maintain its structural and aesthetic properties even when exposed to harsh weather, constant water contact, and abrasive marine conditions.

- Resistance to Oxidation: Chromium content allows the formation of a passive oxide layer, protecting the wire from oxidative damage and preserving its quality and strength over time.

- Versatility in Applications: Suitable for a wide array of marine applications, including but not limited to, ship rigging, marine barriers, offshore structures, and various naval engineering applications due to its durable and corrosion-resistant nature.

- Safety and Reliability: Its resistance to wear and tear and environmental damages assure safety and reliability in marine operations and constructions.

- Welding Suitability: The low carbon variant (SS316L) ensures higher weldability and minimises risks associated with welding-related corrosion.

The Crazy Wire Company is a leading UK based supplier of nichrome, FeCrAl, and stainless steel wires. We specialise in rapid delivery to any location around the country. Our factory is located in Warrington, which is the historic home of the UK’s wire industry.

Check out our blog ‘What You Need To Know About: Stainless Steel Wires’ for more information on resistance wire in general. Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

Reviews

There are no reviews yet.